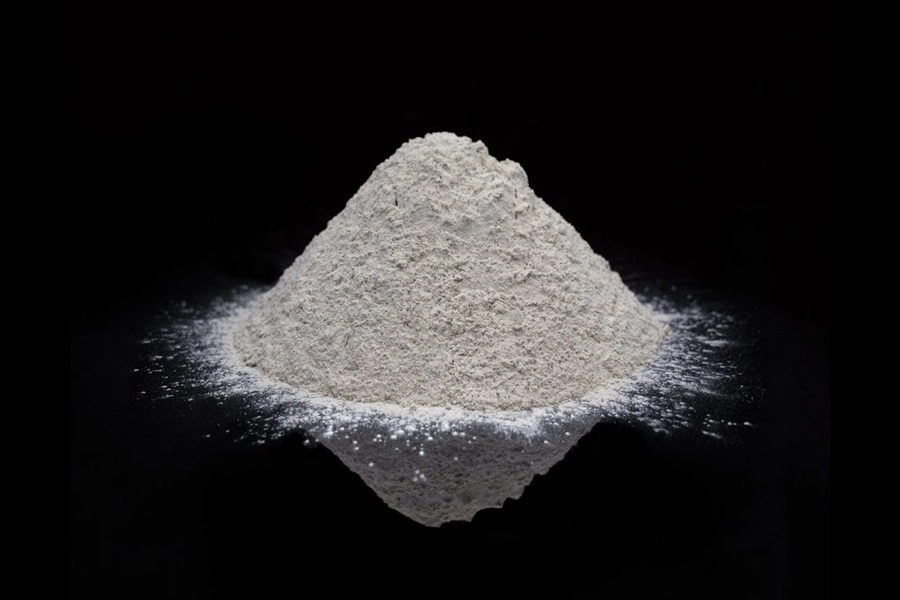

Drilling Bentonite

We’re here to answer your questions and provide assistance

Properties and Functions of Drilling Bentonite

Bentonite is a naturally occurring clay composed primarily of montmorillonite, prized for its exceptional swelling and gel-forming properties. When mixed with water, it forms a highly viscous and stable suspension that serves as a key component in drilling fluids. Key characteristics include:

Thixotropy: Bentonite suspensions exhibit thixotropic behavior, becoming less viscous under shear stress during drilling and regaining viscosity when at rest. This ensures efficient cleaning and stabilization.

Stabilization: The gel-like structure of bentonite drilling fluids prevents the collapse of borehole walls, even in loose or unconsolidated formations.

Cuttings Removal: The high viscosity of bentonite suspensions ensures the effective transport of cuttings to the surface, maintaining a clean borehole for continuous drilling.

Lubrication: Bentonite reduces friction and wear on the drill bit and drill string, prolonging equipment life and improving operational efficiency.

Filtration Control: By forming a thin, impermeable filter cake along borehole walls, bentonite minimizes fluid loss into permeable formations.

Applications of Drilling Bentonite

Drilling bentonite is indispensable in a variety of industries and applications, including:

Oil and Gas Exploration: Used extensively in onshore and offshore drilling operations, bentonite ensures the stability and efficiency of boreholes in challenging geological conditions.

Geothermal Drilling: Its thermal stability makes bentonite an excellent choice for geothermal energy projects.

Water Well Drilling: In water well construction, bentonite stabilizes boreholes and enhances the efficiency of water recovery systems.

Horizontal Directional Drilling (HDD): For pipeline installation and underground utilities, bentonite ensures smooth operations by stabilizing boreholes and managing spoil removal.

Foundation Engineering: In piling and diaphragm wall construction, bentonite provides the necessary support to maintain excavation stability.

Quality Standards: OCMA Grade Bentonite

Our OCMA (Oil Companies Materials Association) grade bentonite meets stringent international standards for drilling fluids, ensuring optimal performance in demanding drilling environments. It offers:

- High Yield: Rapid hydration and gel formation with minimal product consumption.

- Low Filtration Loss: Excellent filtration properties to prevent fluid seepage.

- Consistent Performance: Uniform quality for predictable and reliable results across applications.

Packaging and Supply Options

To cater to the diverse needs of our clients, we offer drilling bentonite in:

- Bulk Bags: Cost-effective options for large-scale operations.

- Smaller Sacks: Conveniently sized for smaller projects or remote locations.

Our flexible supply chain ensures timely delivery to meet your project timelines.